SAGE THERMAL MASS FLOW METER CALIBRATION

Thermal mass flow meter calibration is essential for accurate gas mass flow measurement. Without calibration, the meter’s measurement values are suspect. Flow meters are calibrated during production and most manufacturers recommend annual periodic calibration for recalibration of their meters.

Once the manufacturer has produced the flow meter, the flow meter must be calibrated before it is shipped to the end user. Calibration of the meter ensures that any thermal mass flow meter is measuring accurately. Sage Metering calibrates thermal mass flowmeters in a NIST (National Institute of Standards and Technology) accredited – Traceable calibration facility.

The flow measured by the thermal flow meter is a hypothetical measurement. The instrument measures the power required to maintain the desired heating temperature of the heated sensor above the reference sensor. This relationship between power and mass flow rate is established during calibration. During the design of the sensors, each sensor has different heat transfer properties. Accordingly, each sensor has the correct heat transfer coefficient to measure the correct flow value.

One of the first steps is to precisely calibrate the two platinum RTDs and then characterize the performance of the RTDs at various temperatures within the specified operating range. Since the flowmeter operates on the basic principle of heat, it is necessary to perform this temperature compensation step to ensure that the performance of the flowmeter is independent of the gas temperature.

Sage Metering calibrates as closely as possible to the customer’s operating conditions at the NIST calibration facility. Calibration is performed using real gas or a gas mixture.

In cases where it is impossible to flow the actual gas due to safety or hazardous conditions, calibration takes place using a sampling gas. In this case, modeling based on thermal properties is used to determine the performance of the actual gas.

Data Points

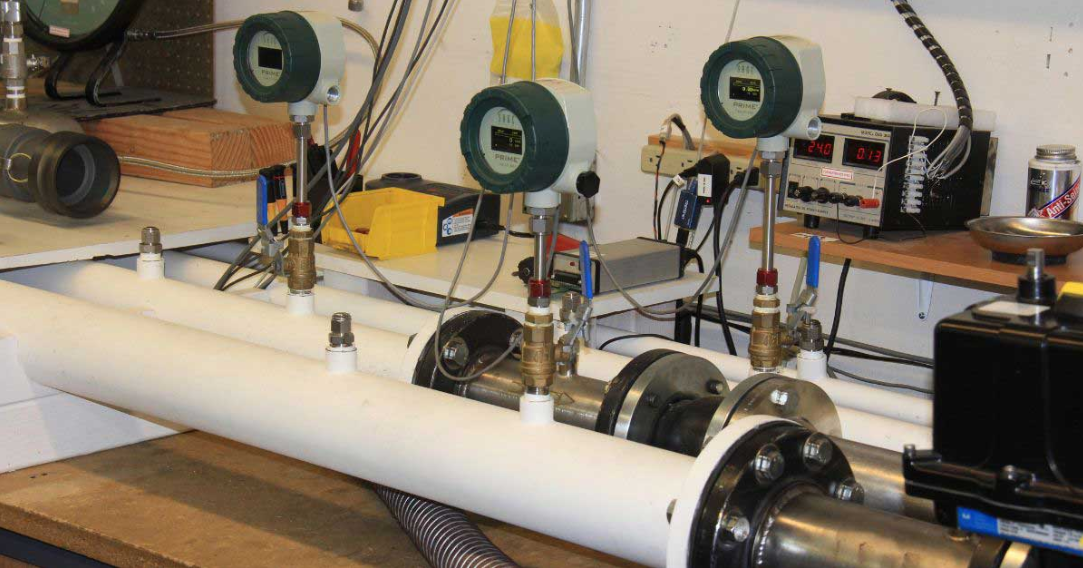

The calibration process involves placing the sensor in one of several different test sections, flowing a known amount of gas through the pipe and then measuring the signal to obtain the desired overheating. These measurements take place at least 12 times over the operating range. The actual flow rate is measured using high precision reference flow meters with appropriate pressure and temperature correction. The reference accuracy is 0.5 %.

Zero Flow Compliance

Once the thermal mass flow meter calibration is complete, the data is reviewed and analyzed. A fifth-order polynomial equation is used to obtain a curve fit of the data loaded into the instrument. The zero-flow data point is crucial for true calibration. The zero-flow data point is a function of gas type and operating pressure. Using a unique zero-flow chamber, Sage achieves a zero-flow data point for the sensor in air at atmospheric pressure and the actual gas at operating pressure.

(Zero Flow Test Chamber)

Sage meters can quickly verify in the field that the meter remains in calibration, saving the user a lot of time and money.